This order required not only key expertise in the design and construction of an energy-efficient hydrogen production plant, but also its complex integration into an existing construction site. Due to the project-specific framework conditions, a high level of plant availability was also required, which meant that a redundancy and equipment concept agreed with the customer

Read MoreThe production of hydrogen and methane from renewable energies or raw materials is an essential building block for the future energy industry. The focus here is not only on technical feasibility, but also on economic feasibility. In recent months, CALORIC has received various engineering orders, which will develop optimised synthesis gas purification concepts based on

Read MoreThis contract is the eleventh contract CALORIC has acquired from Taiwan and our fifth plant in the semiconductor sector. The new hydrogen plant emphasizes the company’s leading market position both in the region and in the semiconductor industry with its’ very high demands in hydrogen purity. The construction method tailored to specific requirements presents a

Read MoreIn the context of a production expansion, which requires an increasing hydrogen demand over the next years, CALORIC could win another order with its tailor-made plant concept “Customized Quality”. The requirements for the plant concept were manifold, among others an extended partial load range was necessary, the minimization of the cooling water consumption was required

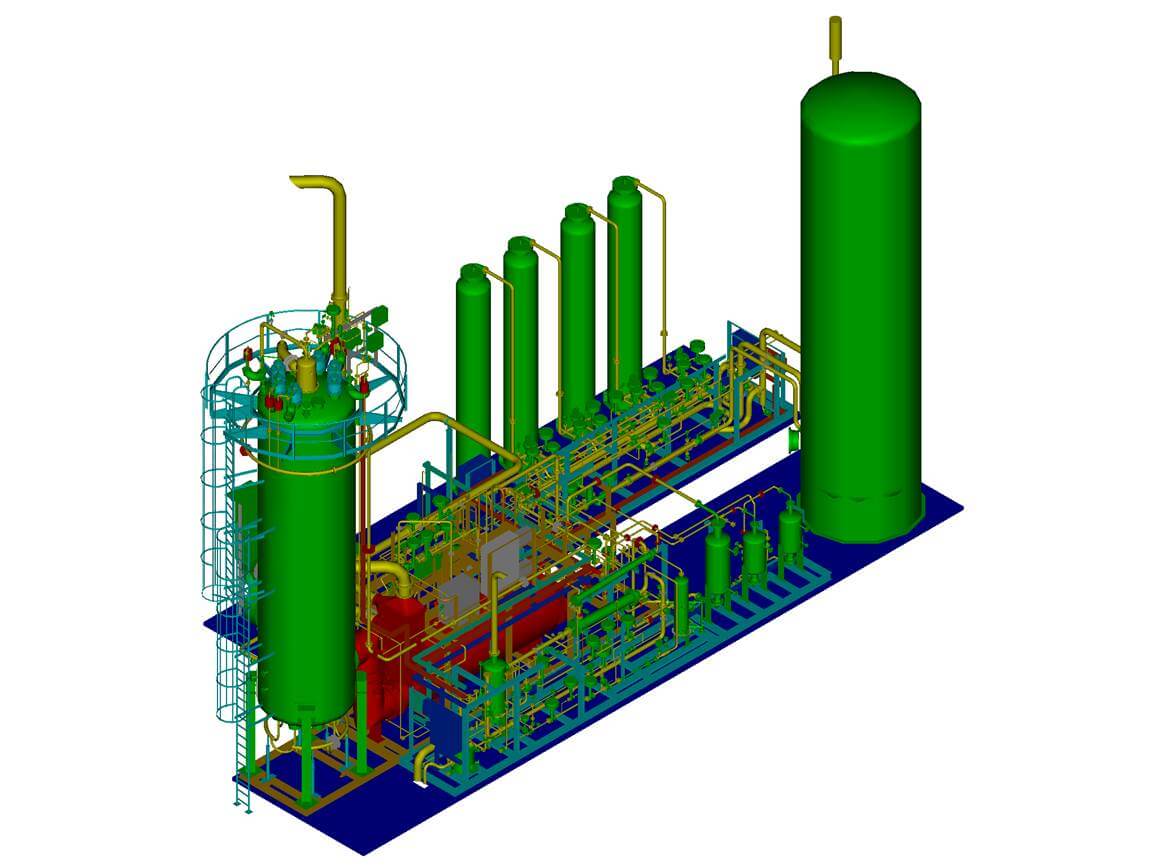

Read MoreCALORIC Anlagenbau GmbH was awarded with a contract to supply a hydrogen plant for client being active in the oleo chemistry in South East Asia. The plant will deliver 1000 Nm³/h pure hydrogen at a pressure of 30 bar. The plant uses the advanced CALORIC HM methanol reforming process by heating the reformer process efficiently

Read MoreFor CALORIC the basis of success was its well-known engineering capabilities to fulfil customer specific requirements in all aspects of conceptual plant design. Beyond the implementation of several operating conditions, requirements for high purity products have to be considered in the concept as well as the limited plot area, which was given and challenging. CALORIC’s

Read MoreThe plant will purify a hydrogen-rich gas to high purity hydrogen by pressure swing adsorption. Due to experience gathered over decades, CALORIC is in position to achieve and guarantee hydrogen purities of 99,9999 percent by volume and more with the pressure swing adsorption technology. By that, the customer, a south-korean research entity, could be convinced.

Read MoreCaloric was selected by an EPC company to provide a hydrogen generating plant based on CALORIC’s advanced Steam Methane Reforming (SMR) technology. The hydrogen plant is part of a new production complex for re-refining of used lube oil in Lithuania. This plant will be CALORIC’s first plant in the Baltic area but the forth plant

Read MoreCaloric was awarded for the third time by an existing Indonesian company to provide a hydrogen generating plant based on CALORIC’s advanced SMR technology. The customer operates already two hydrogen plants from CALORIC based on methanol reforming successfully. As the supply network of natural gas in Indonesia is becoming more and more attractive, clients chooses

Read MoreCaloric was selected by an Indian chemical company to provide a pure carbon monoxide generating plant based on CALORIC’s unique CALCOR® technology. The proprietary CALCOR® process is a dry reforming process of hydrocarbons with CO2. The contract comprises the CO generation as well as the CO purification system based on membrane technology. The CO generator

Read More Caloric Anlagenbau GmbH

Caloric Anlagenbau GmbH